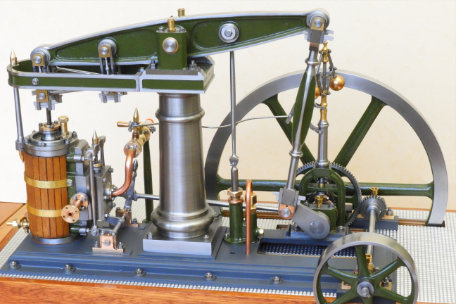

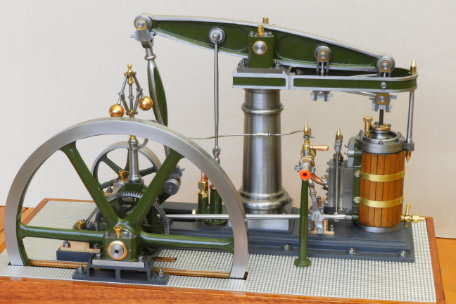

M.E. Beam Engine

Built From Castings

Background

When I retired from work in 2009, I was looking for a suitable project to occupy me in the workshop on those rainy days in Lancashire. I have a bad habit of using the workshop to create bigger and better tools rather than model engineering and I was looking for something with lots of challenging parts to make that would look pretty on display when completed. I finally narrowed the choice to either a Stuart triple expansion marine engine, a Southworth mill engine with Corliss valve gear, or a large-ish beam engine.

The triple expansion engine was tempting, but the finished item would not be able to run on compressed air and would involve boiler making in order to test and run it. In my youth I ran a full size twin cylinder compound mill engine with Corliss valves and one of the engine kits from Southworth Engines looked an attractive proposition. However my lathe is a Myford Super ML7B and the flywheel looked too large to machine in the gap. Southworth were very helpful, and said it could be done, but I decided not to risk it. The Beam Engine won the day.

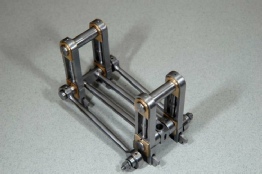

The choice proved to be a good one. Lots of small fiddly parts to make such as the governor and the parallel motion. (Inset).

Surprisingly, the parallel motion has 62 individual parts to make!

Serialised in Model Engineer Alt. Issues

Nos.4603-4643

The Author